SOLUTIONS FOR:

OPERATIONS

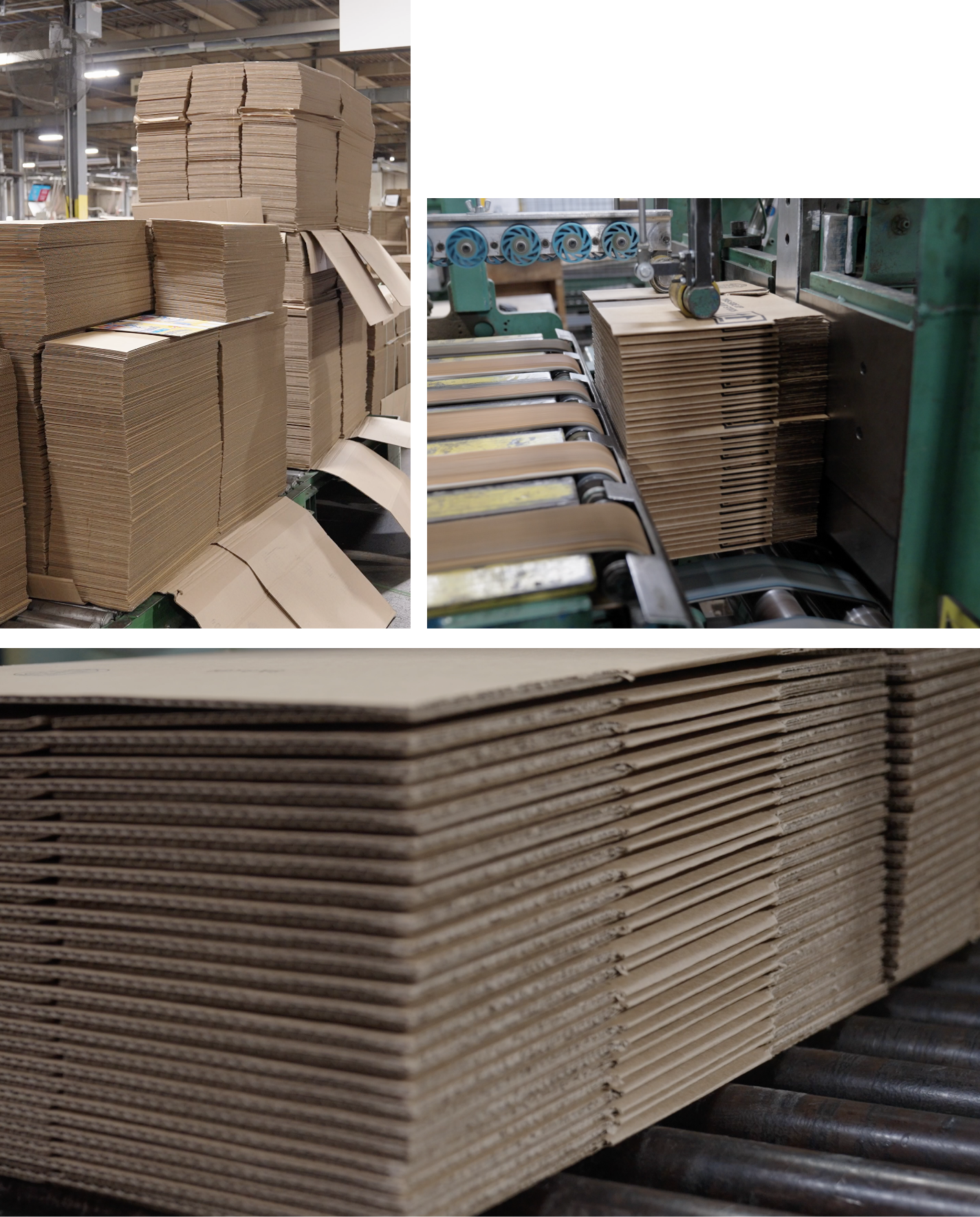

BOXES, BOXES EVERYWHERE

At Tavens we understand that our warehouse costs are the same as your warehouse costs. Storing your boxes on our floor does not reduce the cost of the boxes. It simply moves that cost from one warehouse to another.

Corrugated packaging has strange economics. The product is cheap, but it is also large and bulky. This makes calculating the true cost of the box a bit more complicated. But it can be done.

The first step is acknowledging that not having a box incurs the highest possible cost. Any cost calculation must recognize the real value of a box is its availability at the time of shipment. The inability to ship products has significant downstream negative costs that far exceed the cost of the packaging.

Once we recognize that core fact, then we can begin thinking about how we ensure that we always have the boxes at the lowest possible cost.

For many customers this means buying boxes from distributors, who maintain inventories for immediate release. But this does not actually reduce the cost of warehousing, it just moves it from your building to theirs. At Tavens we attack the problem differently.

The key is understanding overall usage, demand interval and variability.

Tavens developed a proprietary system that allows us to help our customers capture and manage this information in real time.

We work with you to lower the overall cost of ownership for both of us, by orienting our production to meet the just in time requirements of your customers. Because we are a corrugated manufacturer, we manage inventories much more closely than a distributor, who relies on someone else to produce the boxes.

Thinking carefully about these three key dynamics, we right size your order quantities to ensure packaging availability at the lowest possible cost.

BOXES ARE CHEAP

Spending dollars to save cents.

A survey of corrugated buyers and users report missed due dates, low OTIF (On-Time In-Full) ratings and a consistent problem with mis-manufactured boxes. They report that the number one problem they face is maintaining an adequate number of boxes to ensure operations is not impacted by a lack of corrugated packaging. This is especially true of customers who are engaged in end of line packing and the ecommerce segment where same day shipment is a critical customer value.

The second issue they cite as a major problem is managing a wide array of SKU’s that consume a lot of warehouse space. The two problems are related.

As a buyer, not having a box is a high visibility failure. It shuts down production, delays order fulfillment and drives down customer satisfaction in a very public and tangible way. To prevent this very negative outcome, buyers have learned to rely on themselves. They are forced to build “safety stocks” of the corrugated packaging, which has a host of hidden costs, because they cannot rely on their vendor to make and keep commitments.

The corrugated industry loves this solution. It allows them to pass long the costs of failure to their customers. Additionally, they get to run larger quantities, reduce shipment costs, eliminate storage costs and perform badly without any real-world impacts.

At Tavens we find it amazing that customers are willing to put up with this for a few percentage points off a product that is already very inexpensive.

We solve the problem differently.

RAPID RESPONSE

Not a slogan, not a marketing concept, a way of life. A strategic choice.

Everyone in manufacturing understands that setups cost money. The goal in life is to maximize the time each machine is producing product. Down time is the enemy of productivity and profit. Setups equal downtime.

This is especially true of the corrugated companies. Every box company is obsessed with maximizing square footage through the plant. The reason for this is simple. Making boxes is not where the money is in the corrugated business. The money comes from making the paper used to make the boxes.

Boxes are cheap. They are customized. They can be very complex to manufacture. The goal is always to simplify, consolidate and maximize the machinery. Once we have the box set up on the machine we want to run as many as we can. But here’s the thing, boxes are also bulky and expensive to store. And we don’t want to store them.

At Tavens we think about the problem differently. We know that our customers do not care about boxes. They just want to ship product. And sometimes the cost of not being able to ship product is extremely high. We asked ourselves how can we support those customers that need boxes in a hurry, for whatever reason?

The answer is Rapid Response.

We inverted the traditional question and stopped trying to maximize the machine hours and instead asked how can we maximize setups? How can we do the one thing our customers care about, instead of the one thing we care about?

SAFE QUALITY FOOD CERTIFIED

SQF certification is a food safety program that demonstrates compliance with global food safety standards. It’s recognized by retailers, brand owners and foodservice providers worldwide.

What does SQF certification mean?

-It’s a valuable accreditation for business.

-It’s based on Hazard Analysis Critical Control Points (HACCP)

-It’s recognized by the Global Food Safety Initiative (GFSI)

And most importantly it assures Tavens can safely handle all of your food packaging needs!